Introduction

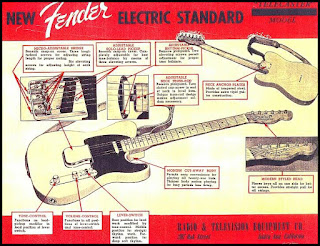

I've got to say, choosing the parts for the build has been quite a challenge. After ordering a 1951 style neck, I decided it would be good to try and get hardware to match. I'd already bought a 97mm standard bridge to cover that enlarged pickup routing, so it wasn't going to have the traditional ashtray style. I does at least have just three saddles. But now I was starting to be concerned that it wasn't going to work, but more about that at a later date. Here's a photo of most of the parts, before I started building. |

| I've been busy on Ebay |

Mounting the Tuners

I really like the idea of split shafts on the Kluson tuners. The guitar string goes down the hole in the middle, so there's no sharp end waiting to spike you. But what I thought would be a simple job, became complicated.The vintage Fender neck is supposed to have 9mm tuner holes. The Kluson's are a simple pressed steel design, authentic for this era, but the press-in bushes were too loose. The holes in the neck were actually 9.4mm with the bushes being 8.6mm, so I was a little confused as to whether I'd bought a 9mm neck or a modern style 10mm one. I could pay £10 for the 10mm bushes, but that felt like a lot to pay, I'd then still have to open the holes a little, and I'd have to delay the project.

In the end, I painted the inside of the holes with varnish (about 5 coats) until they fit snuggly.

Fitting The Neck

If you buy a non-fender body, the specs may not be standard, and in my case this was definitely true. In my case the over-all shape is slightly different, and the neck was loose in the neck pocket. If left like this I would always have re-alignment problems whenever I took the neck off.The solution is simple enough, I glued a piece of veneer to the bottom side of the pocket.

|

| A small piece of veneer makes the fit snug. |

|

| The neck fitted and complete. |

I now had something that looked like a guitar, and the next step is fitting that bridge. It turned out to be a problem, so I'll cover that in the next blog.

Thanks for reading.